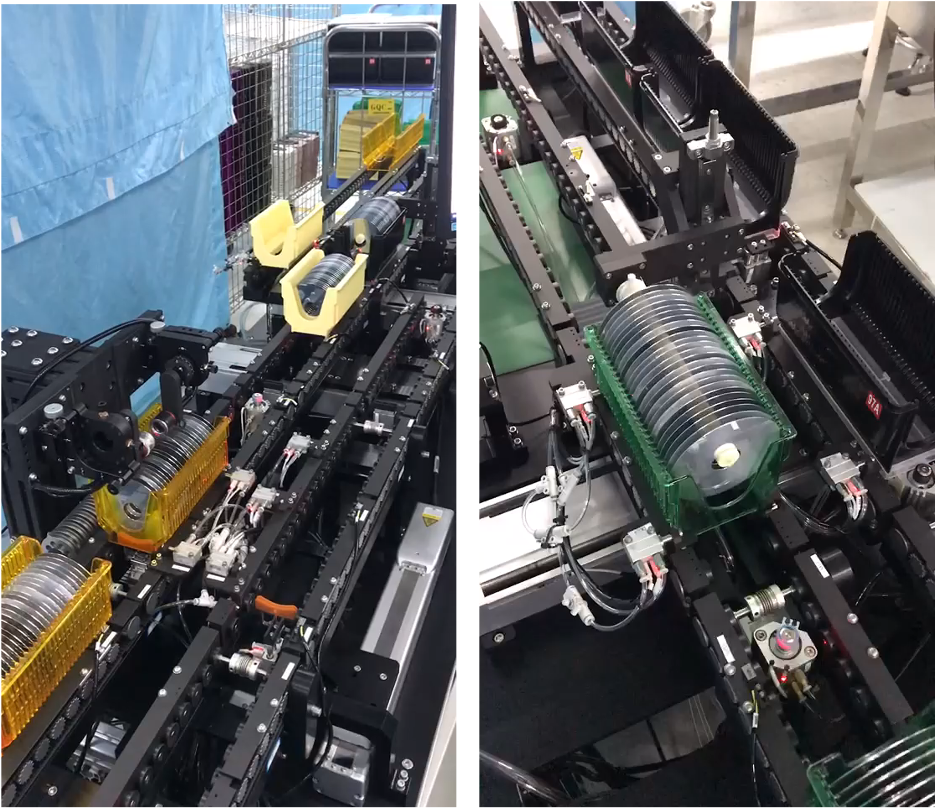

A High speed and high precision automatic laser thickness measurement system

We developed this system in 2019. It is the first automatic online thickness measurement system in this field. All the process system status can be real-time monitored. Therefore, all the process data can be traced. The communication interfaces and data protocols can be customized for different applications. It runs 24 hours a day and has continuously worked for more than 28 months by the end of Apr. 2022.

An automatic loading and unloading system of a double-sided grinding machine

This system was developed in 2021. It is an efficient automation solution in the application. We developed the control algorithm and the host computer software. It can save 3 persons every two grinding machines.

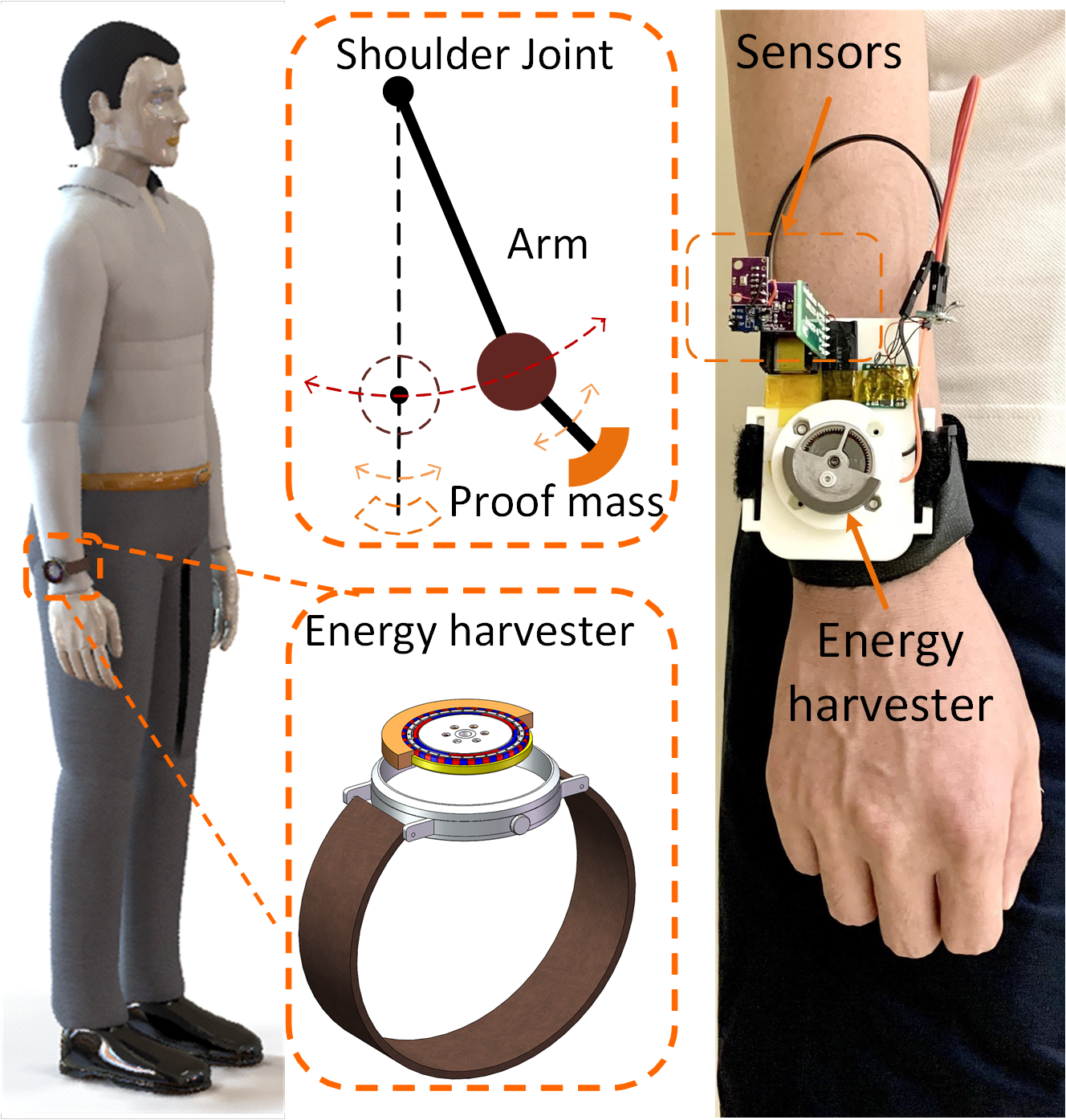

Embedded energy harvester for batterless wearables

Wearable devices, such as smart watches and wristbands, require sustainable power supply. However, chemical batteries cannot satisfy this requirement due to finite energy capacity. Harvesting energy from human limb swinging renders a promising solution to this issue. Motivated by this, we have developed embedded energy harvesters for the wearables and IoT sensors. Our energy harvesters can efficiently scavenge kinetic energy from human motion to provide sustainable power for the wearables. With our patented technologies, our energy harvesters improve output power and power density by an order of magnitude compared with the counterparts. It has attracted great attention from the industry, and we are working with our industry partners to commercialize this project.

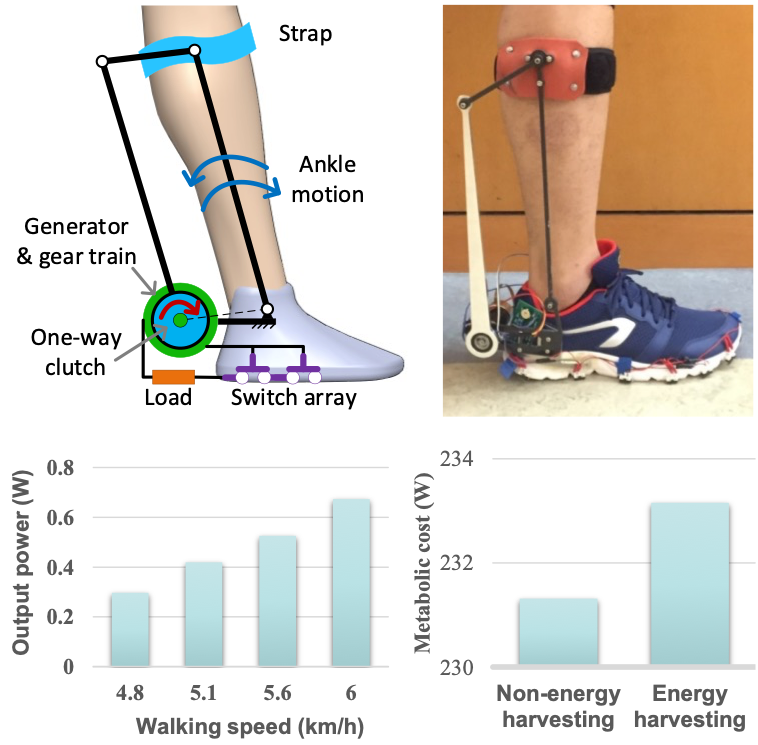

Smart energy harvester for power generation and walking assistance

Capturing kinetic energy of human motion provides sustainable power for the wearables. However, would it increase human effort when harvesting kinetic energy? In this project, we validated that the energy harvester can generate electricity while reducing metabolic expenditure of the user. For this purpose, a smart energy harvester has been developed to identify and capture negative work of human ankle. The negative work identification system does not require power supply since it is designed based on human gait characteristics. We demonstrated that our energy harvester generates maximum power of 0.67 W, but reduces metabolic expenditure by 0.84 W. This technology has great potential in exoskeleton, rehabilitation robots, and individual soldier equipment, etc.

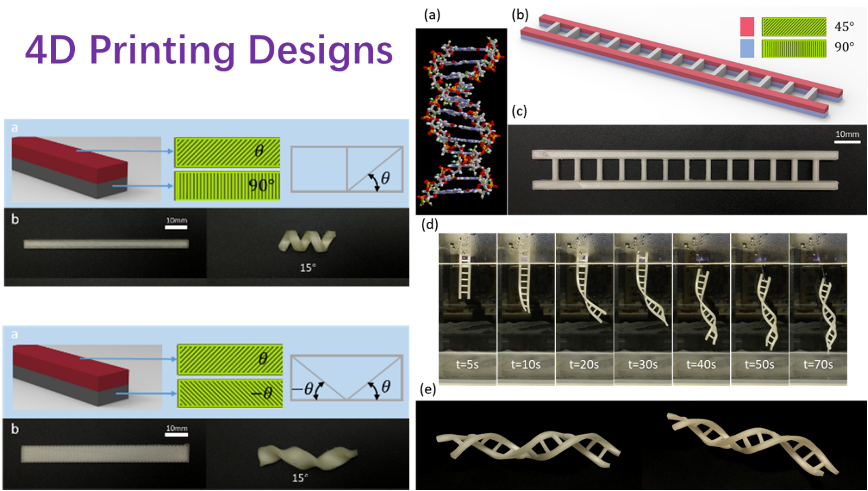

4D Printing and Smart Structures

4D printing is a combination manufacturing technology of 3D printing and smart materials. It means 3D printed structures can perform a shape change into a new structure by certain stimuli. As figures show that simple and flat structures can become into complex helical, twisting and DNA structures. We realized our designs by controlling printing path and the properties of smart materials. We are able to produce smart structures with unique function, excellent mechanical strength, and special physical properties. For example, we designed an adaptive Poisson’s structure with our 4D printing technology. Therefore, 4D printing opens opportunities for many fields, such as robotics, aerospace, and drug delivery, etc.